Maintenance and servicing of industrial equipment

Scheduled servicing and maintenance of industrial equipment, troubleshooting of automation and mechanics.

In many cases, in the presence of a breakdown of an industrial unit, there is no need to rush it

out and replace it with a new one - after professional repairs using quality

components and applying scheduled machinery maintenance,

the installation will function properly for a long time.

Scheduled servicing and maintenance of industrial equipment, troubleshooting of automation and mechanics.

In many cases, in the presence of a breakdown of an industrial unit, there is no need to rush it

out and replace it with a new one - after professional repairs using quality

components and applying scheduled machinery maintenance,

the installation will function properly for a long time.

On-site troubleshooting

Industrial machinery is usually stationary, bulky, so that in the event of a certain

unidentified failure, it is not possible to relocate the entire equipment for repair. For this

purpose, the industrial device is serviced at the installation site, where the device is

diagnosed and the faulty unit is identified. After selecting the original or non-inferior

replacement components, the device is repaired.

Industrial machinery is usually stationary, bulky, so that in the event of a certain

unidentified failure, it is not possible to relocate the entire equipment for repair. For this

purpose, the industrial device is serviced at the installation site, where the device is

diagnosed and the faulty unit is identified. After selecting the original or non-inferior

replacement components, the device is repaired.

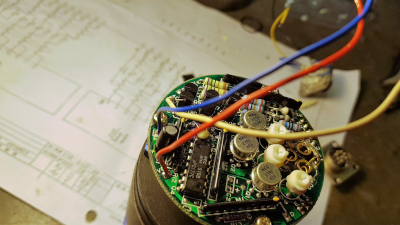

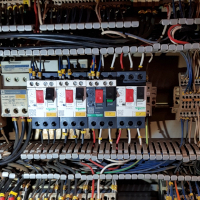

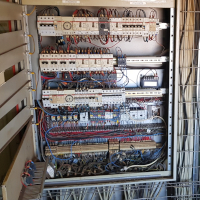

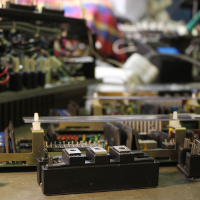

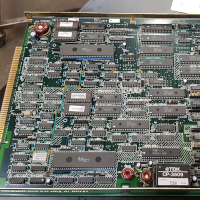

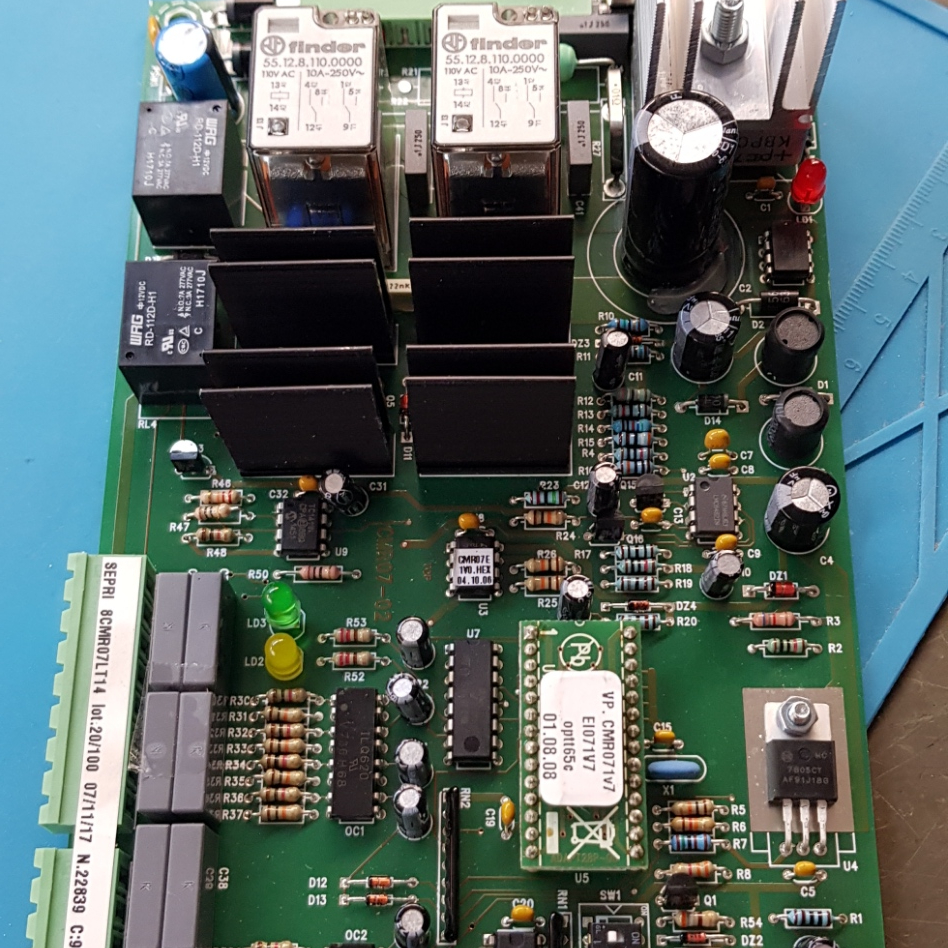

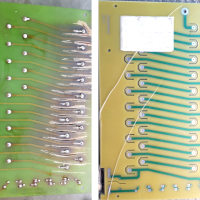

Repair of industrial modules

- Electronics and automation modules: power supply units (PSUs), inverters, frequency converters (VFDs), controllers, port expansion (I/O ) boards, PLCs, etc.

- Electromechanical devices: electric motors, spindles, various types of servo-drives, contactors, etc.

- Mechanical parts: shafts, rollers, bearings and their blocks, screws and their couplings, gears, etc.